|

|

|

Adsorbant carrier for BIOFILM TECHNOLOGIES |

| |

LEVAPOR carrier are innovative, designed materials with variable ideal properties, allowing taylor made solutions for a wide field of applications in biofilm reactors.

|

|

|

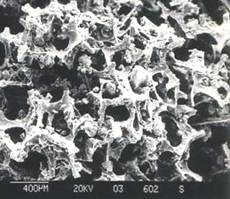

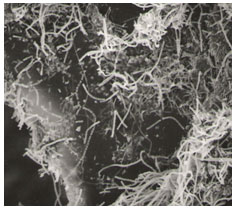

| LEVAPOR-carrier: cross section and colonised by anaerobic bacteria |

|

| |

| PROPERTIES |

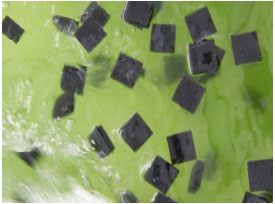

| LEVAPOR carrier are comprising of, porous, flexible, easily fluidisable plastic foam cubes, impregnated with adsorbing pigments. They become colonized very fast by specialized microorganisms, resulting in bioprocesses with remarkably higher efficiency and stability, regenerating the adsorbing capacity biologically. |

| |

|

|

LEVAPOR carrier in fluidised biofilm reactor |

|

| |

| FIELDS OF LEVAPOR APPLICATION |

- Biotreatment of municipal and industrial effluents , especially in

nitrification /denitrification and removal of persistent and hazardous

pollutants .

- Biological gas treatment, including acidifying pollutants,like chloroorganics,

mercaptans, NH3 and H2S.

- Processes applying reuse of water, like fish hatcheries and aquacultures.

- Fermentation of bioproducts

|

| |

| Selected treatment plants using LEVAPOR- fixed microorganisms |

|

|

|

|

| Anaerobic-aerobic Plant for biotreatment of toxic pulp mill effluents |

Two-step bio-trickling filter (BTF) purifying polluted air in a sludge

treatment plant |

|

|

|

|

| Multistage anaerobic-aerobic plant for treatment of chemical site effluents |

Combined, biological-physico-chem. treatment plant for treatment of

complex industrial groundwater |

|

| |

| Benefits of LEVAPOR-supported biofilm technologies : |

- Higher efficiency and stability of bioprocesses under

- Lower excess biomass production

- Lower degree of reactor filling : only 12 to 15 vol.% instead of 30 to 70 % as usually practicized in reactors with non modified plastic carriers

- Higher removal of persistent, hazardous pollutants via

- Buffering of toxic shock loadings

- Short startup period of bioprocesses

- Remarkable process economy and Simple technology, applicable also during plant operation .

|

| |

| Additionally to LEVAPOR carrier |

we do offer also our services in designing taylor made problem solutions, based on 40 years experiences on biofilm technologies both in science and in the practice. Our tools are:

- Analysis of the problem

- Elaboration of alternatives for problem solution , supported by

- Practice oriented biotests (optional),

- Process Design and/or Engineering

- Production and delivery of the required LEVAPOR type and

- Plant startup using optimized mixed biomass, enriched with microbes essential for degradation.

|

| |

| |

| |